What is X-Ray Radiography (XRR)?

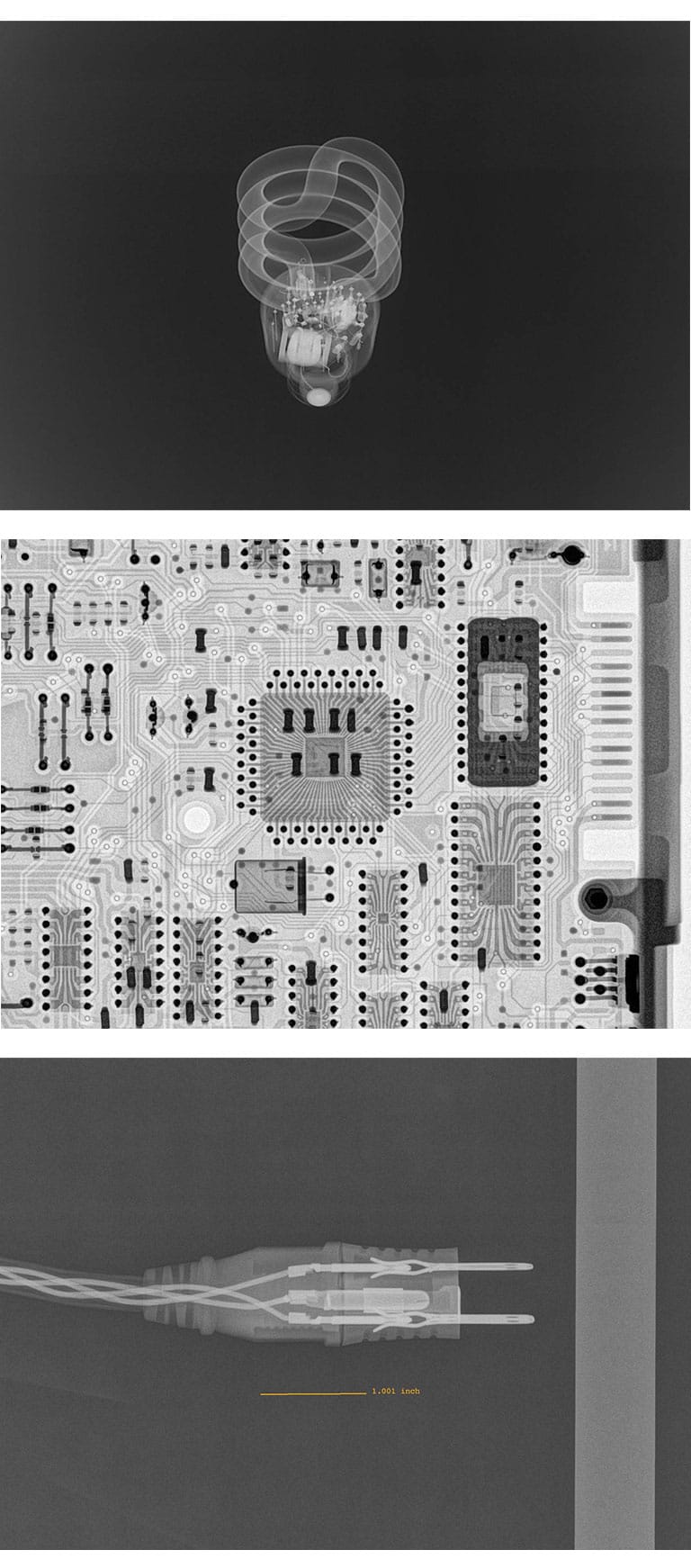

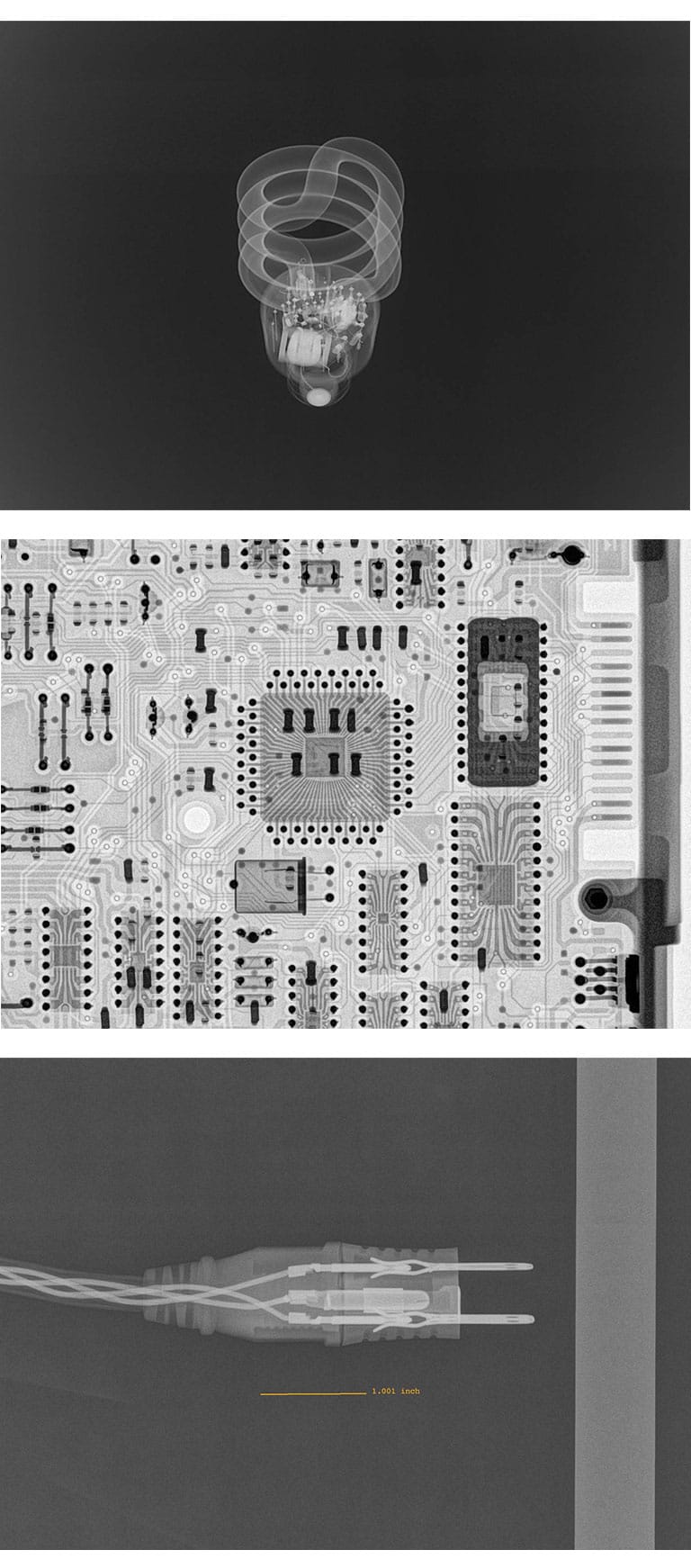

X-Ray Radiography (XRR) in the context of materials testing is a non-destructive testing (NDT) technique used to examine the internal structure of materials without damaging them. This method involves the use of X-rays to create images of the internal features of a material or component. This technique involves the use of X-rays to inspect the internal structure of materials without causing any damage or alteration to the object being examined.

What information can X-Ray Radiography provide?

XRR is widely used in various fields for materials testing due to its ability to detect internal flaws, such as cracks, voids, and inclusions, as well as for inspecting the quality of welds and assessing the integrity of components. Its applications include:

- Aerospace and Automotive: For inspecting critical components like engine parts, landing gear, and welds to ensure safety and reliability.

- Electronics: To examine solder joints and detect defects in circuit boards.

- Art and Archaeology: For investigating the internal structure of artifacts without causing damage.

- Construction: To inspect steel reinforcement in concrete structures, and detect corrosion or damage.

What Materials can be analyzed using X-Ray Radiography?

It is particularly useful for identifying flaws, defects, or irregularities within a wide range of materials, including metals, plastics, ceramics, and composites.

Golden Engineering 270 kV X-Ray Source