FTIR Testing :contamination due to Packaging

Contamination Due to Sample Packaging in FTIR Testing

The packaging and transportation of evidence or substances that require laboratory testing are extremely important steps. Unfortunately, packaging and transportation can be given less priority than necessary. When testing for the material composition of an unknown substance, incorrect packaging and handling can affect the outcome of testing resulting in contamination. One common area where the outcome of testing is frequently affected due to incorrect packaging, is the sampling technique of Fourier-Transform Infrared Spectroscopy (FTIR) known as Attenuated Total Reflection (ATR). What type of incorrect packaging could affect the technique of ATR though?

A common practice in the field of forensics is to place samples in reusable bags often under brand names such as Ziploc®.

Polyolefin Films & Slip Agents

Reusable bags are made from films of polyolefins such as polyethylene. To remain competitive many of these polyolefins must be produced at an increased rate of speed, yet run into the problem of friction due to the viscid nature of the films [1]. To counter the problem of friction, many manufactures add a slip agent which migrates to the polyolefin surface and reduces the coefficient of friction between films and machinery [1].

Slip agents vary, but one commonly observed slip agent is a fatty acid amide known as stearamide

To demonstrate slip agent contamination, a mock sample submission was created at Micron inc. A customer submits an unknown polymer for testing to determine the material composition [/et_pb_accordion_item][/et_pb_accordion][et_pb_text _builder_version=”3.27.4″]Stearamide is also frequently used because it exhibits properties of an anti-blocking aid, a substance which helps reduce the adhesion between films [2]. Slip agents and anti-blocking aids may aid in the production of polyolefins, but can contaminate submitted samples. The migration of a slip agent such as stearamide to the surface of a polyolefin can cause transferable contamination. Migrated slip agents can be rubbed onto any substance placed into a reusable bag, even if contact is made for a brief period of time.

To demonstrate slip agent contamination, a mock sample submission was created at Micron inc.

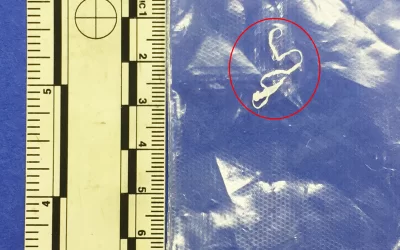

- Figures 1 & 2: A customer submits an unknown polymer for testing to determine the material composition

- Figure 3: After analysis using FTIR-ATR the sample was determined to be polytetrafluoroethylene (PTFE), but additional absorptions are present that do not correlate with PTFE

- Figure 4: An additional analysis was performed on the reusable bag which the unknown polymer was received in. The reusable bag was identified as the polyolefin known as polyethylene using FTIR-ATR

- Figure 5: Again additional absorptions were present that do not correlate with polyethylene. A slip agent was suspected, isolated, analyzed using FTIR-ATR, and was identified as stearamide

- Figure 6: A final comparison spectra of the unknown polymer, a reference of PTFE, and a reference of stearamide displays the contamination of the slip agent from the reusable bag onto the sample submitted for testing (Figure 6).

An additional analysis was performed on the reusable bag which the unknown polymer was received in. The reusable bag was identified as the polyolefin known as polyethylene using FTIR-ATR

Again, additional absorptions were present that do not correlate with polyethylene. A slip agent was suspected, isolated, analyzed using FTIR-ATR, and was identified as stearamide (Figure 5). Final comparison spectra of the unknown polymer, a reference of PTFE, and a reference of stearamide display the contamination of the slip agent from the reusable bag onto the sample submitted for testing.

Samples can potentially have absorptions that are imperative for identification distorted from the presence of slip agents. To remove the slip agents sometimes samples need to be washed in solvent. However, it is possible for samples to be sensitive to solvents and a solvent wash is not always a viable option. This is why at Micron inc. it is recommended that all samples being sent in reusable bags be wrapped in aluminum foil or paper if possible to prevent slip agent contamination.

1. Chen, J., Li, Hu, & Walther. (2007). Fundamental study of erucamide used as a slip agent. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 25(4), 886-89

2. Zahedi, A., Ranji, A., & Asiaban, S. (2006). Optimizing COF, Blocking Force, and Printability of Low Density Polyethylene. Journal of Plastic Film & Sheeting, 22(3), 163-176.