Private Conference Rooms

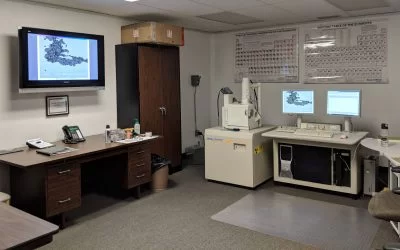

Group Viewing Screens

Testing protocols lay out the course of the inspection for the day. Prior to booking you will want to ensure that our facility can accommodate all the testing needed.

Along with all of our regular testing we are equipped with a class 100 clean room, and sample preparation. Portable band saws, a table saw and grinders are are frequently used to prepare cross sections and obtain smaller cut samples for testing.

Get in touch directly by giving us a call, sending us an Email or filling out the “Schedule an Inspection” Form on this page.

Helpful Things to Include:

• Protocol or a List of testing you need

• a Range of Dates for Inspection

• Questions

A Retainer fee is required to hold a date for Inspection. The cost will be applied to all testing through out the inspection.

The Retainer must be paid in full prior to the day of inspection.

• Reference Micron Invoice # on payment

Evidence may be dropped off between 8:30am – 5pm Monday through Friday. Large Deliveries are accepted at the garage on the far right corner of the building. A pallet jack is on site but no delivery dock is available.

Please provide a Chain of Custody Sheet. Evidence transport is not provided

Micron’s facility is hidden. Download directions to avoid getting lost with the GPS.

We are located behind the Mercedes Benz of Wilmington on Route 48 in the back right corner lot.

+ Retainer Forms (to be provided at booking)

+ Hotels

+ Local Restaurant on Diner’s, Drive in’s & Dive

Attendees will be asked to sign in on a group inspection sheet for documentation. Once the evidence has been gathered and all parties have arrived the inspection will begin.

Wifi will also be provided.

A knowledgeable Senior technologist will advise on proper sample preparation and the best course of testing. Videography and photography is welcome for documentation. Separate Conference rooms will be available for private discussion of the case.

Once the inspection is concluded each attendee will leave with a copy of the sign in sheet. Any Data gathered may be provided on a USB flash drive or mailed once more testing is concluded.

On occasions samples may be sent out for more testing.

Services

General Applications

Metal Phase Analysis

Heat Treatment Quality Control

Defect Analysis in Castings

Case Depth Measurements

Fracture Analysis

Contaminant Analysis

Polymer Identification

Plating Defects

Stainless Steel Passivization Measurements

Grain Size Measurements

Internal Defects Determination

Corrosion Product Analysis

Failure Analysis

applications

Thermal Analysis: DSC, TGA

Surface Analysis: Auger, ESCA

Polymer Analysis: FTIR

Surface Topography: Keyence Digital, SEM

Hardness: Vickers, Knoop, Rockwell

Chemical Analysis: EDS